Organobentonite drilling mud

- (Whatsapp) 0086-13185071071

Bentonite Drilling Applications

Oil-based drilling fluid-specific rheological additive organic bentonite, which is a natural bentonite primarily composed of montmorillonite with a layered structure, is produced through ion exchange intercalation with organic coating agents, making it a modified Organobentonite drilling mud. When exposed to oil, solvents, and liquid resins, it swells into a gel-like state. Under appropriate shear stress and chemical action, it exhibits excellent thixotropy, viscosity, suspension properties, and high-temperature stability.

Organobentonite drilling mud

Traditional economical organo bentonite

CP-2

Organo bentonite can be used in gravure printing ink, screen printing ink, oil pen ink,

CP-982

Organophilic clay is suitable for drilling fluids based on mineral oil, diesel oil, and synthetic oil.

CP-992

Organic bentonite is used in lubricating grease to maintain high temperature stability.

CP-250A

Organoclay for solvent based and water based paints and coatings.

Using Method

Organobentonite drilling mud

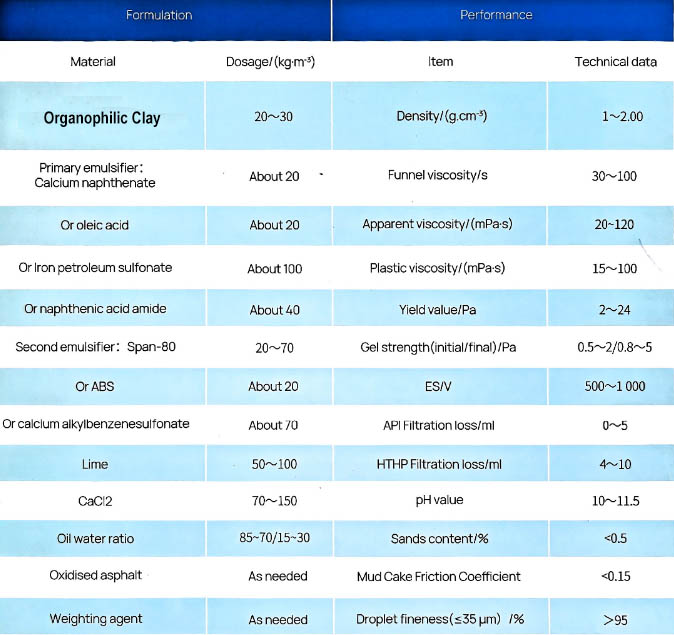

In oil-in-water drilling fluids, we recommend using an Organobentonite drilling mud organo clay additive at a dosage of 25–40 kilograms per cubic meter. As a thickening rheology modifier, the dosage can be adjusted according to the formulation requirements. The primary factor influencing the dosage is the type of base oil used, which may result in varying dosage levels.

Generally speaking, mineral oils, synthetic oils, and modified vegetable oils require significantly higher amounts of organic bentonite compared to diesel. For fully oil-based drilling fluids, adding a small amount of water or a small amount of polar activators (such as methanol, ethanol, or propylene carbonate) can achieve more desirable results. However, adequate shearing is necessary to ensure effective dispersion and achieve the desired initial viscosity.

Bentonite drilling grade Organoclay

Recommended Formulation for oil based Drilling mud

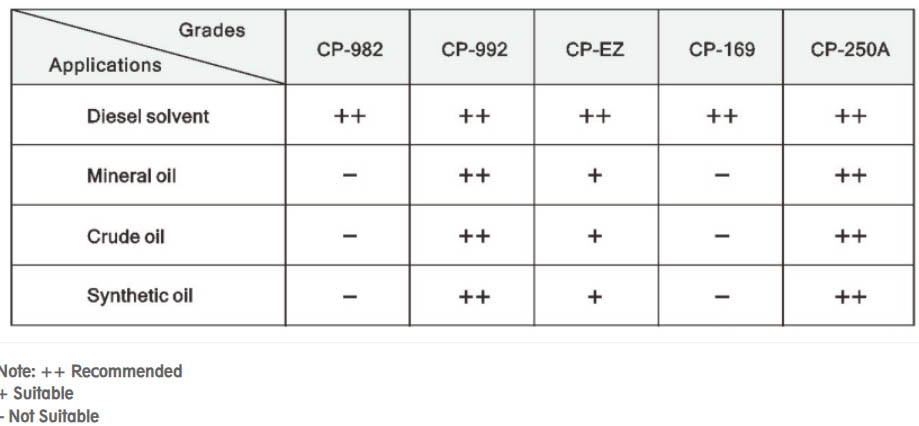

Organophilic clay for different Base oil:

- For Diesel Based Mud

- For Mineral Oil Based Mud

- For Synthetic oil Based Mud

- For Linear and isomerized Alpha Olefins

- For Modified vegetable oil

Organophilic clay for Viscosifying drilling Fluids:

- All oil based drilling fluids

- Invert emulsion fluids

- Workover fluids

- Fracture fluids

Recommend Polarity Activator

Acetone,

Methanol(95%),

Ethanol(95%),

Propylene carbonate,

Ether detivatives

Packages & Shelf Life

1, 25Kgs /Bag or 50Lb/Bag(22.68kg)

2. 1000Kgs / Pallet or 800Kgs/Pallet

3. 16MT/20FCL With Pallet, 18MT/20FCL without Pallet. 25MT/40FCL with Pallet.

4, Organoclay has a shelf life of at least two years from the date of manufacture.

advantages

Effectively suspends weighting materials and other solids

Maintains suspension over a wide temperature range

Eliminates need for chemical activators

Is easy to disperse and rapid yielding

Suspends weighting materials and other solids

Bentonite for Drilling

Organophilic clay is suitable for drilling fluids based on mineral oil, diesel oil, and synthetic oil.

Organoclay For Comestic

As a thickening rheology modifier, it is used in cosmetics such as nail polish and lotion.

Organic Adsorption Media

Organoclay is a proprietary granular media that is highly effective in adsorbing organic compounds

The most direct effect of using organic bentonite in drilling fluid, especially in drilling fluid with organic system, is to prevent sedimentation, and to show stable suspension performance, as well as lubricity and lubrication of drilling tools. At the same time, it can resist salt and pollution, and is particularly suitable for complex formations. At some high temperatures, especially above 180°C, it can still maintain the stability of the entire drilling.

We recommend that you apply our organic bentonite to deep wells and shale wells. After using our organic bentonite, the suspension, stability and lubricity of oil-based mud can be achieved in one step, ensuring the stability, safety and efficiency of your drilling.

You should select different types of Organobentonite drilling mud based on the base oil of your oil-based drilling fluid. In particular, we use and recommend different organic bentonites for diesel systems, mineral oil systems, and synthetic oil systems.

Our Organobentonite drilling mud CP-2 is mainly used in diesel systems, our CP-982 and CP-992 are mainly used in mineral oil systems, and our CP-250A is mainly used in synthetic oil systems under high temperature and high pressure conditions.