Microspheres for Drilling Fluids | hollow glass beads can increase the volume and rock-carrying capacity of the drilling fluid, which helps to improve the drilling efficiency.

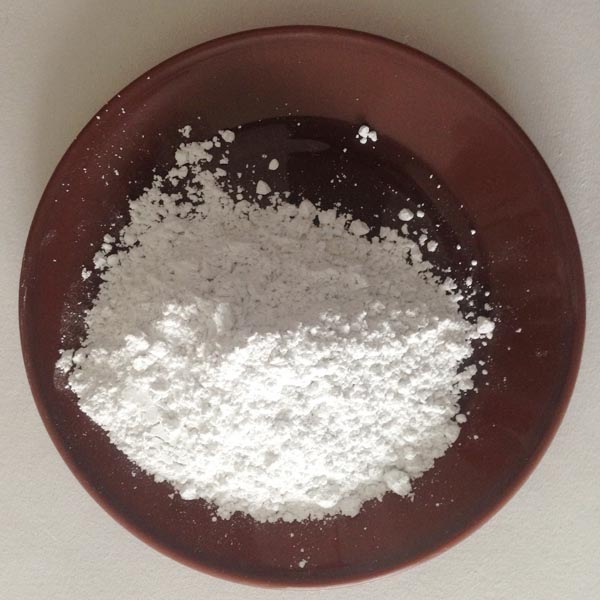

Microspheres for Drilling Fluids

What Are Bead Blasting’s Applications?

| Aerospace industry | Remove rust and paint from mechanical components to remove knife marks. |

| Remove scratches on the rubber | Reflective paint for roads |

| Scratch treatment on the surface of stainless steel. | |

| Foundry industry; | Pre processing in the electroplating industry. |

| Semiconductor Industry | Crafts for exterior decoration |

Microspheres for Drilling Fluids

Hollow glass beads have a wide range of applications in oilfield drilling. The following is about the specific applications and advantages of hollow glass beads in oilfield drilling:

1. Mode of application:

o Hollow Glass Microspheres (HGM) are very small, hollow glass beads with air inside. Hollow Glass Microspheres are used to formulate low density drilling fluids.

Due to its low density, high compressive strength, good flowability and other characteristics, and will not react with the chemicals in the mud, to ensure the chemical stability of the drilling fluid .

o Hollow glass beads are also used in the preparation of cementing mud can be formulated with low-density, high-strength mud system, which is one of the effective ways to solve the problem of low-pressure, easy to leakage well cementing mud leakage and low return .

Size of glass beads for blasting

Model of Bead blasting glass | Sieve Size (mesh) | Particle Size Range(μm) |

WSL17L# | 20~40 | 425 ~ 850 |

WSL 18L# | 30~40 | 425 ~ 600 |

WSL 19L# | 40~60 | 300 ~ 425 |

WSL 20L# | 60~100 | 150 ~ 300 |

WSL 21L# | 70~140 | 106 ~ 212 |

WSL 22L# | 100~140 | 106 ~ 150 |

WSL 23L# | 100~200 | 75 ~ 150 |

WSL 24L# | 140~200 | 75 ~ 106 |

WSL 25L# | 140~270 | 53 ~ 106 |

WSL 26L# | 200~325 | 45 ~ 75 |

Specification of Bead blasting glass

| Specific gravity | 2.4-2.6 g/m3 |

| Stacking density | 1.5g/cm3 |

| Type | Blasting / Shot Peening Media |

| Spherical | |

| Rockwell hardness: | 46HRC |

| Mohs | 6-7 |

| Round rate | 80% |

| Melting point | 710-730 ℃ |

| Index of refraction | 1.5—1.6 |

Advantages:

o Chemical stability: hollow glass beads can increase the volume and rock-carrying capacity of the drilling fluid, which helps to improve the drilling efficiency.

o Density and Strength: Hollow glass beads have very light weight and can be used as an additive to the drilling fluid to reduce its overall density, high compressive strength, which is easy to mix low-density drilling fluids and ensure constant density of the drilling fluid, as well as to ensure the normal transmission of MWD signals.

o Fluidity and Lubricity: Hollow glass beads can increase the volume and rock-carrying capacity of the drilling fluid.

o Fluidity and lubricity: Hollow glass beads are spherical in shape, with excellent fluidity and excellent lubricity, which is needed not only to carry rock chips, but also to cool and lubricate the drill bit, reduce bit wear, dramatically increase drilling speed, and improve operational capacity .

o Recyclability: Hollow glass beads in drilling fluid can be recycled and reused, reducing production costs.

o Multifunctionality: In addition to the above characteristics, hollow glass beads are also resistant to corrosion, high temperature, high pressure and other properties.

The addition of hollow glass beads can improve the viscosity and cuttings of drilling fluid and enhance the stabilizing effect on the well wall.

o Hollow glass beads have good compatibility with cement slurry additives, which can effectively reduce the density of cement slurry, and the rheology of cement slurry is good, which can form a good spatial network structure with cement slurry, with good stability . We welcome you to inquire about our hollow glass beads.