Organo Bentonite Suspension Agent: Organoclay bentonite is an important presence in the petrochemical industry. It is used as an efficient suspending agent and stabilizing thixotropic agent.

It is also an ideal rheological additive, which meets the different base oils used in the oilfield drilling industry, whether your base oil is diesel oil or mineral oil, which is often referred to as white oil, or synthetic oils, we have a corresponding organic clay bentonite model to recommend to you to meet the requirements of different base oils formulations, and ultimately to achieve ideal rheological and suspending properties and thixotropic properties. And in some high temperature and high pressure environment. Our organic bentonite also always maintain a stable performance.

We recommend that you use the organophilic clay bentonite, in strict accordance with the organoclay bentonite to join the order and steps to join the use, because the wrong order of joining will directly affect the performance of the organic bentonite itself. Currently in Russia, Canada and other regions have special requirements for high-temperature and high-pressure drilling mud fluid and completion fluid.

In these extreme environments, our high-temperature, high-pressure, stable organiclay bentonite has obvious advantages over traditional organic clay bentonite. You can decide which is the more cost-effective organobentonite to use by requesting free samples for testing, and determining the amount of additive you need to use as this will affect the performance of your final formulation.

Organo Bentonite Suspension Agent: Preventing Delamination in Stored Drilling Muds

Organoclay Applications

Organo Bentonite Suspension Agent: Preventing Delamination in Stored Drilling Muds

Organophilic Clay is an easy dispersing, self activating organoclay that exhibits high performance efficiency in diesel, low aromatic mineral oil, modified vegetable oil and synthetic base fluid formulation. CP-150 unique rheological structure suspends weighting materials and other solids with less increase in viscosity and gel strength than conventional bentonite. It is highly effective in distillate and mineral oil based invert fluids.

Organoclay Bentonite is used for Oil drilling Mud,

Paint,coatings, inks, grease and domestic etc.

Base oil:

- Diesel Oils

- Mineral Oils

- Synthetic Oil

- Linear and isomerized Alpha Olefins

- Modified vegetable oil

Viscosifying drilling Fluids:

- All oil based drilling fluids

- Invert emulsion fluids

- Workover fluids

- Fracture fluids

Organoclay Advantages

- Effectively suspends weighting materials and other solids

- Maintains suspension over a wide temperature range

- Eliminates need for chemical activators

- Is easy to disperse and rapid yielding

- Suspends weighting materials and other solids

- Maintains suspension over a wide temperature range

Composition of Organoclay

Organically modified bentonite clay

Appearance Off white to tan finely divided powder,

Moisture content (105℃,2hr) ≤3.5%

Specific Gravity 1.7

Bulk density 0.40~0.60g/cm³

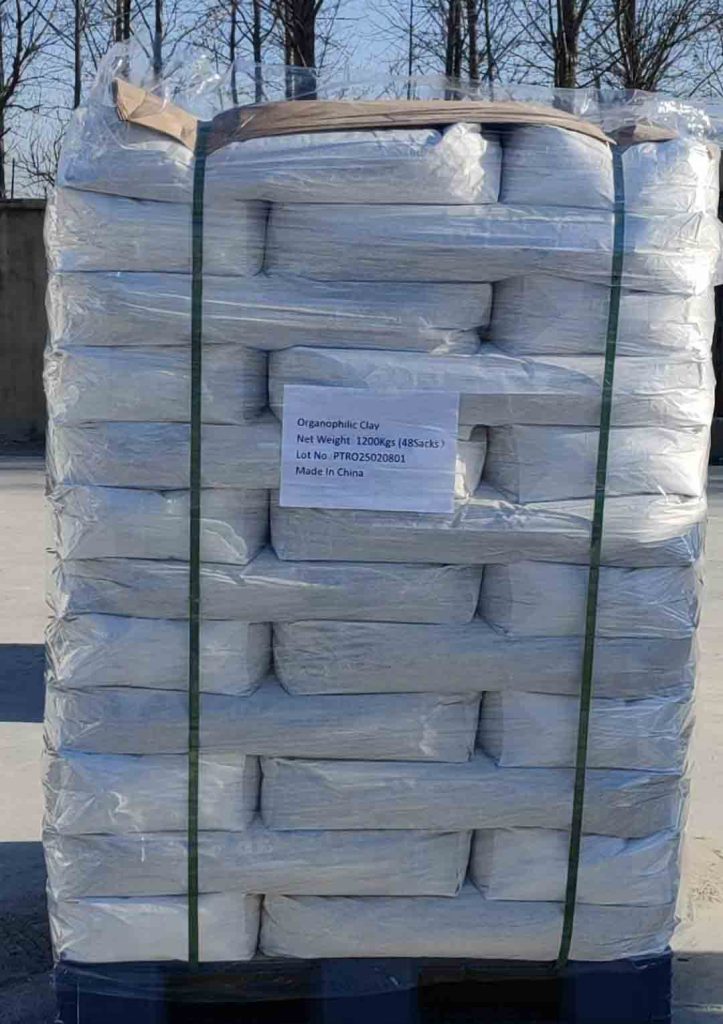

Organobentonite Packages

Kraft paper bag with PE liner or multi-wall paper sacks or customized. 25kg/bag or 22.68kg/bag or customized.

Organophilic clay Store in a dry, well-ventilated area with temperature of 0℃-30℃. Keep container closed. The quality guarantee period is 24 months.