When it comes to organoclay for coatings, it is a key additive made from bentonite.

Taking advantage of the layered structure of montmorillonite in bentonite and its characteristic of swelling and dispersing into colloidal particles in water or organic solvents, it is manufactured by incorporating organic covering agents via ion exchange. This non – metallic mineral presents as white or light yellow solid powder with layered solid particles.

In coating systems, organoclay boosts viscosity, thixotropy, and anti – settling performance through interlayer water absorption, swelling, and ion exchange. It slightly enhances system adhesion, leading to effective atomization of spray materials and neat, tight particle arrangement.

In contrast, hydroxyethyl cellulose (or ethyl hydroxyethyl cellulose), an organic non – ionic solid from etherification, increases viscosity but reduces atomization and particle arrangement, highlighting organoclay’s unique benefits for coatings.

The CP series of organic bentonite is mainly used in solvent-based and water-based paints, coatings, inks, lubricants, cosmetics, and oilfield drilling fluids.

Rheology modifiers are an organo clay (modified bentonite), designed especially for use in solvent based system. Organic Clay can be used widely in solvents from low polarity to medium-high polarity.

Properties

Composition Organic derivative of a montmorillonite clay

Appearance Fine powder, light yellow

Moisture content (105℃,2hr) ≤3.5%

Loss on ignition (1000℃) 28%-31%

Bulk density 0.53g/cm3

Fineness (<74μm, %) ≥98%

Organoclay for coatings

- High gelling efficiency,high viscosity

- Wide application range, it can be applied in all low, middle and high polarity range

- Produce reproducible thixotropic consistency over a wide temperature range

- Imparts particle suspension, preventing hard settling of pigment and fillers

- Exerts strong film reinforcing action in organic binder systems

- Organoclay for coatings

Application of Organo clay

Organo clay is used in the following applications:

- Marine paint, Industrial paint, heavy-duty, anticorrosion paint such as bituminous coatings, epoxy paints, chlorinated rubber paints

- Grease

- Inks

Sealant

Organoclay for coatings

Using

Organo Bentonite disperses under high shear and requires a polar activator for best efficiency. Heat is not required to obtain good dispersion. Addition levels are typically in 0.2%~2.0%. Polar activator (95% Ethanol or 95% Methanol) is needed. Normally addition level of polar activator is recommended to be 45%~60% of CP-40 in weight. If in xylene system, addition level of polar activator is about 30%-40% of CP-40 in weight.

Pre-gel is made as below procedure.

- Charge solvent to mill

- Slowly add CP-40 (6-10% by weight of total pre-gel) to mill under agitation.

- Mix at high speed for 5 minutes.

- Add polar activator.

- Mix at high speed for 5 minutes.

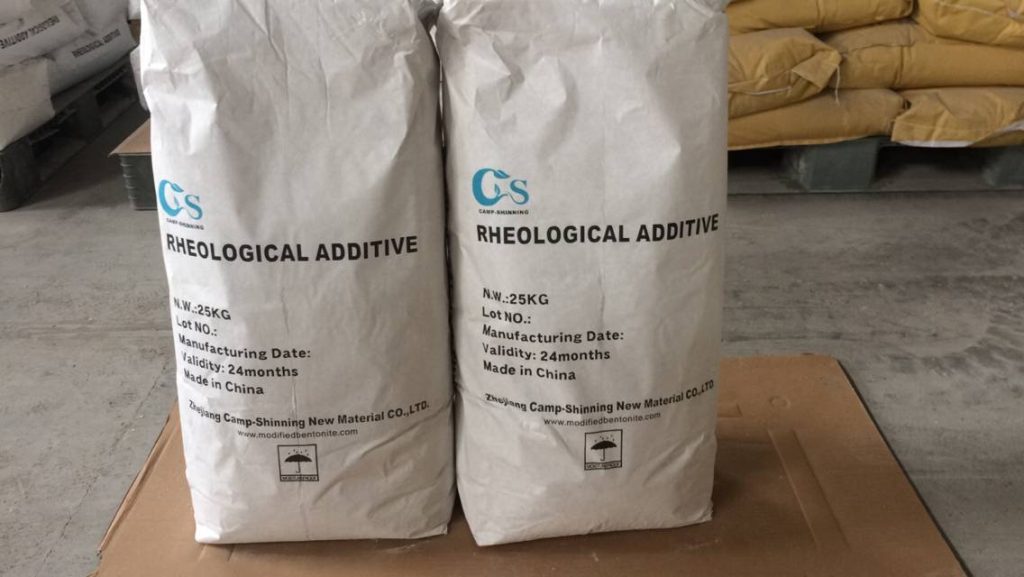

Package

Kraft bag or kraft complex interior with PE or customized

Storage

Organic bentonite clay has a shelf life of 2 years, and should be stored in a ventilated, cool and dry place.

Safety

All safety information is provided in the Material Safety Data Sheets for Zhejiang Camp-Shinning New Material Co.,Ltd..

Email: [email protected]

Whatsapp : 0086-13185071071