Struggling to find the right rheology modifier for your oil-based products? Organoclay might be your solution.

Organoclay are chemically modified bentonite additives used in paints, coatings, inks, grease, oilfield drilling fluids, and cosmetics (like nail polish and lotions) to improve texture and stability. They work in both oil-based and water-based systems, such as latex paints.

When choosing additives, knowing the right product is just half the battle. Let's dig deeper.

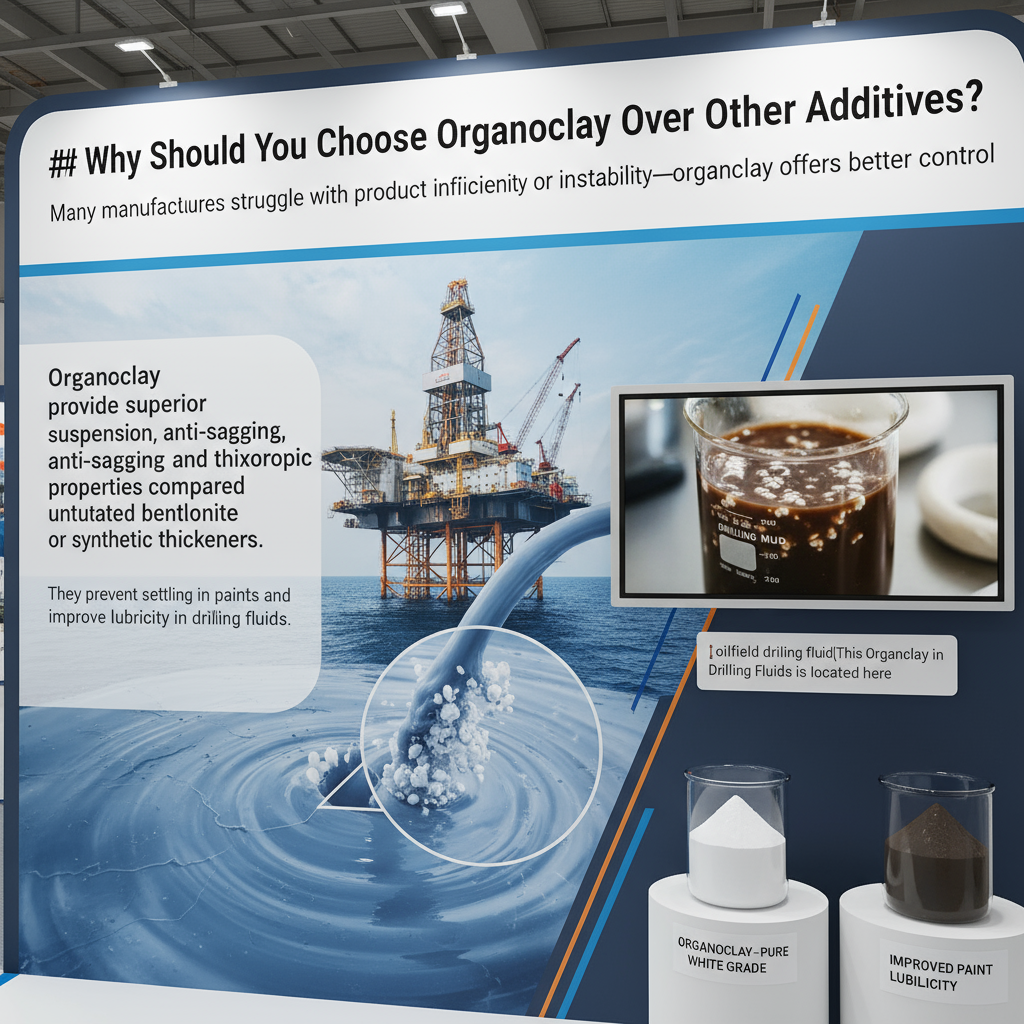

Why Should You Choose Organoclay Over Other Additives?

Many manufacturers struggle with product inefficiency or instability—organoclay offers better control.

Organoclay provide superior suspension, anti-sagging, and thixotropic properties compared to untreated bentonite or synthetic thickeners. They prevent settling in paints and improve lubricity in drilling fluids.

Key Benefits in Different Industries

| Industry | Key Advantages |

|---|---|

| Paints & Coatings | Prevents pigment settling, enhances brushability |

| Oilfield Fluids | Improves viscosity, reduces fluid loss |

| Greases | Boosts thermal stability |

| Cosmetics | Smooth texture, prevents separation |

Many suppliers focus only on paints, but Camp Shinning specializes in oilfield drilling applications. We tailor solutions for different needs.

Common Misconceptions

- "All organoclays perform similarly." Wrong—formulations differ based on application.

- "They're hard to disperse." Proper activation techniques solve this.

Camp Shinning helps clients avoid these mistakes with hands-on guidance.

How Do You Pick the Right Organoclay Supplier?

Buying organoclay without expertise leads to wasted time and money.

A reliable supplier should offer technical support, product customization, and quality assurance—like Camp Shinning, with 20+ years in oilfield and industrial applications.

What Sets Camp Shinning Apart?

- Own bentonite mines: Ensures raw material consistency.

- ISO 9001 certification: Guarantees international standards.

- Batch tracking: Samples stored for future reference.

Clients in "Belt and Road" countries trust us because we solve problems like:

- Paint cracking: Adjusted organoclay grades prevent this.

- Drilling fluid failure: Custom blends enhance performance.

Questions to Ask Your Supplier

- Can you tailor organoclay for my specific needs?

- Do you provide technical support post-purchase?

- How do you ensure batch-to-batch consistency?

Many buyers regret not asking these earlier.

Conclusion

Organoclay enhance products from paints to cosmetics. Partnering with experts like Camp Shinning ensures optimal performance.