Whether it is cosmetics for personal use or the entire formula for paint production(rheology modifiers in paints), it contains many active ingredients. Most people are not aware of the characteristics and functions of each ingredient. Today, our post will explain in detail the formula ingredients used in personal cosmetics or paint coatings, namely rheological modifiers. What exactly are they? How do they work? And, what performance can it enhance after use? Rheological meaning is clear.

What is Rheology?

What are Rheology Modifiers and How Do They Work? “If you want to clearly use and understand rheology additives, it is very important to know what they actually are. Put simply, they are a physical property significantly associated with the deformation and flow of solid, liquid, and gaseous materials.

When sufficient force is applied to the material, it begins to enter a state of flow. Currently, rheology additives | rheology chemistry are used in many different application fields including personal care products, that is, cosmetics, and the paint industry(rheology modifiers in paints), biology, oil drilling industry, lubricant industry, and so on. The viscosity of rheology additive(viscosity modifier)s in these application fields is a key factor that enables the manifestation of their rheological properties.

When rheology additives exert their rheological properties, no matter what the application field, both their yield strength, which is the stress point when materials start to flow, and their viscosity, that is, the material’s resistance to flow, are several important indices.”

what is rheology? rheology chemistry,we hope our answer could help your questions.

What Are Rheology Modifiers?

What are Rheology Modifiers and How Do They Work? The thickening rheological agent simultaneously enhances the stability and consistency of the product, and improves the appearance characteristics of the product. A thickener is another name for a rheological additive; its primary function is to change the flow properties of a material while maintaining the stability of the entire formulation. It controls the characteristics of the finished product by increasing viscosity.

Different Types of Rheology Modifiers

The rheological additives currently available on the market come in a wide variety, each suited to different application fields. For example, some rheological additives are hydrophilic, meaning they have the function of absorbing water. Others are hydrophobic, capable of removing moisture. Hydrophilic rheological additives can be used as suspending agents, thixotropic agents, and anti-settling agents. Whether in cosmetics, paint(rheology modifiers in paints), or coatings, they all perform certain functions.

Inorganic Materials

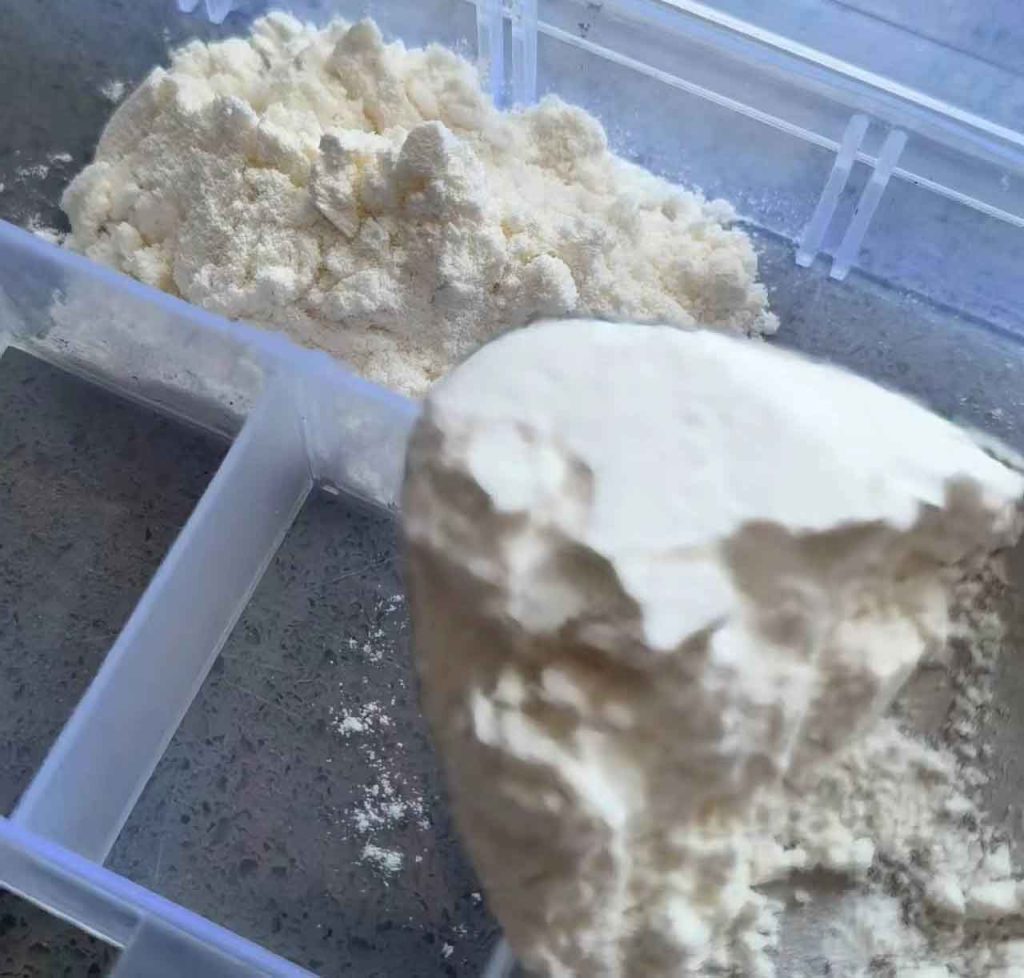

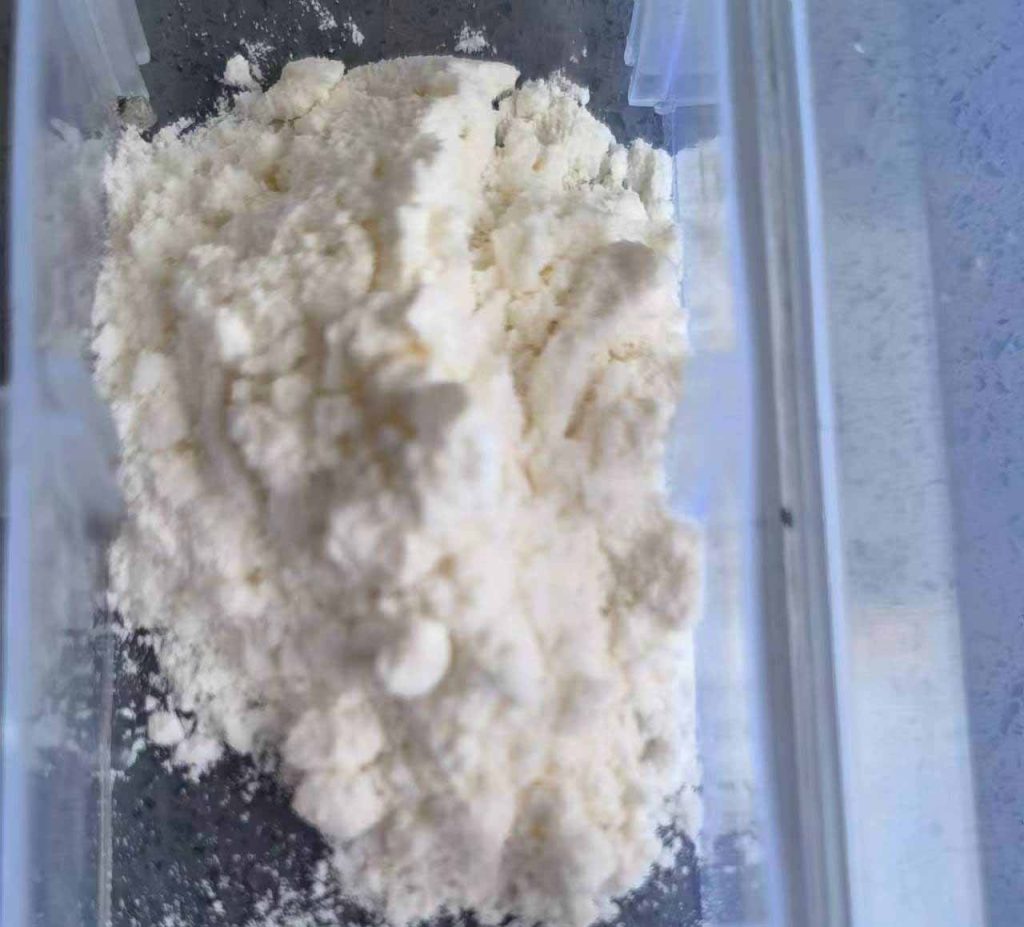

What are Rheology Modifier and How Do They Work? “We provide a large amount of high quality organic rheology modifiers to our customers, who use them in paints(rheology modifiers in paints), coatings, cosmetics, lubricating grease, and oil drilling fluids. Our organic bentonite is a type of pre-gelling product used as a thickening and rheology modifier, which can also be used directly in dry powder form. It offers very stable performance, regardless of how long it is stored, it does not segregate, thus providing anti-settling properties.

At the same time, it provides excellent thixotropic characteristics, making it suitable for use in thickening various types of oleaginous systems. We also provide organic bentonite for inorganic systems, that is, water-based systems, used as thickening rheology modifiers, hence our products possess suspension performance and an excellent high-gelling effect.

Our Rheology Modifiers

What are Rheology Modifiers and How Do They Work? Everyone knows that rheology modifier, through adjusting the viscosity of the drilling fluid(viscosity modifier), can enhance the efficiency of oil-water separation. This is why many people choose organic bentonite as the thickening rheology modifier during oilfield extraction. In the printing ink industry and the coatings industry, rheology modifier have demonstrated excellent rheological and thickening properties.

So if you are an oilfield excavator, please boldly choose our organic bentonite as the suspending agent for your drilling fluid. This will indeed be a very correct decision. If organic bentonite is used as a thickening rheology modifier in paint, it’ll make your painting work, especially during brushing, feel much smoother and more uniform, while its anti-sag properties will perform exceptionally well.They are all belong to Properties of rheology.

What are rheological additives used for?

The rheological additive is mainly used in solvent-based systems, serving as a thickener and thixotropic agent. It can be widely used in lubricating oils, drilling fluids, sealants, fracturing fluids, inks, personal care products, and industrial coatings.

What is the rheology modifier for oil?

This powder-like rheology agent is an organic gelling agent that can improve the rheological properties and suspension characteristics of drilling fluid, mainly under relatively low shear rates. It still maintains a relatively stable strength of viscosity and gel to improve cleanliness in the drilling holes, and it also transports rock cuttings out of the well.

Organic Gelling Agent/Rheology Modifier

Learn More

If you have any further queries about our rheology modifier, or if you’re interested in our products and want to experiment to see if they suit your formulation, please feel free to contact our sales team. We believe that our free samples can enable you to better serve your market and customers in practice. Therefore, when you contact us, you will receive our friendly technical support and more down-to-earth price support. We look forward to cooperating with you.

What are Rheology Modifiers and How Do They Work?

Rheology modifiers are sometimes also called viscosity modifiers or thickeners. They can not only improve the good rheological properties of the entire formula, but also have thickening properties and other relatively stable properties. Reflected.

The packaging of this white powder organic bentonite is mainly in 50-pound bags or 25-kilogram bags. Of course, we also accept special packaging requirements from customers. Current 20-foot containers can hold 16 tons with pallets, and 40-foot containers can hold 25 tons.

We sincerely welcome you to inquire about our organic bentonite and thickening rheological agents, which will help you achieve maximum improvement in production or trade.

No matter if you have any questions or needs about thickeners and rheological agents, feel free to contact us now.