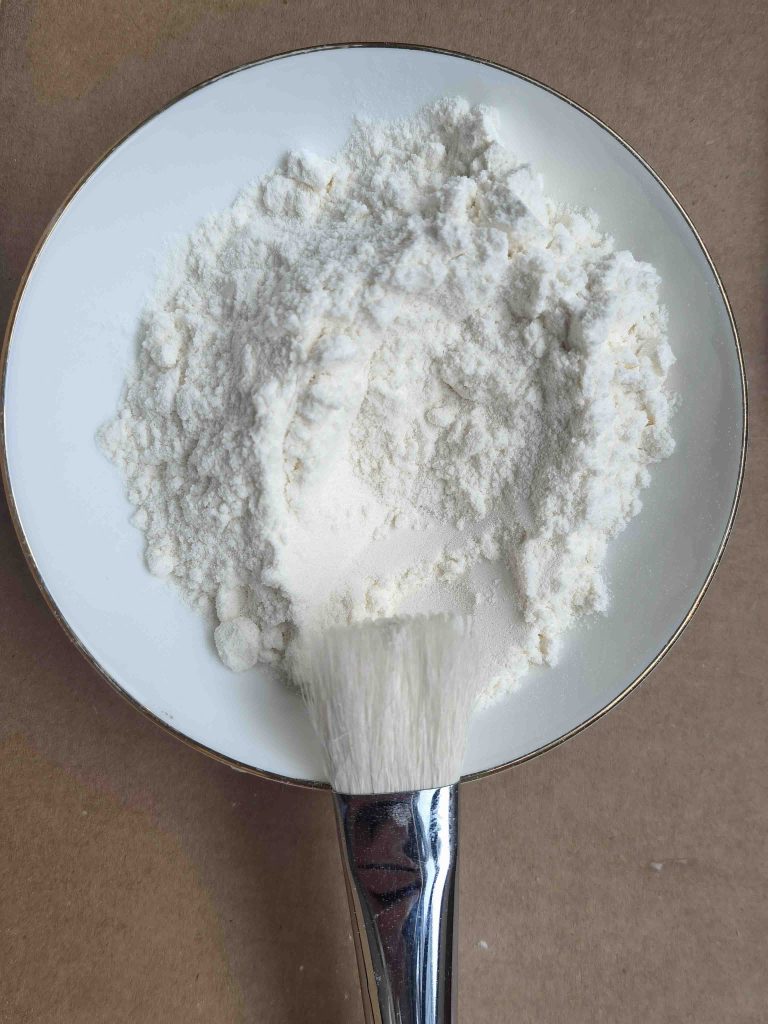

organo bentonite | organic clay

Organo bentonite clay is also called organic clay bentonite or organophilic clay and rheology modifier. It is a modified bentonite clay which widely used in various fields of industry, such as lubricating grease, paints, inks, oil drilling mud, etc. Its role is more to show its rheological properties, universal anti-settlement properties, sagging properties, etc. in these fields.

Types of Organo Bentonite:

Although our current main application is in oilfield drilling mud fluids, whether your base oil is mineral oil, synthetic oil, or diesel, we have a corresponding organophilic clay bentonite recommend to you.

Here, we mainly talk about the application of organo clays bentonite in paint.

One of the major applications of Organic Bentonite Clay is to be used in paints and coatings, both waterborne and oilborne paints can be used with Organo clay Bentonite, they can be used in both waterborne and solventborne systems to achieve the effect of preventing pigment settling, preventing sagging, and to achieve stabilization at elevated temperatures.

As a leading global supplier and manufacturer of Organiclay Bentonite, we can provide you with high quality thickening and rheological agents. Depending on your application, we solve your pain points and give your paint coatings better thixotropic and rheological properties.

Our Organic clay Bentonite Clay prevents pigment settling in static high viscosities and ensures silky smoothness during your application in dynamic low viscosities, easily achieving the goal of anti-sagging.

In other words, after using our Organo Bentonite Clay in paints and coatings, the anti-sagging performance can be improved by at least 50%, which can reduce your rework costs.

At the same time, it is only necessary to add the amount of paint coatings, between 1% and 3%, and traditional organobentonite than, it has a very big economic advantage, so no matter whether your formula is a water-based system or solvent-based coating system, you can choose our organo clay bentonite.

As early as 20 years ago, we applied organoclays bentonite to industrial coatings, which greatly helped paint and coating manufacturers to optimize costs, achieve high thixotropy and very stable pigment suspension.

We can say very frankly that our organophilic clay bentonite can be dispersed quickly in solvent-based systems, in water-based systems, with stability at high temperatures and cost-effective, and at the same time help you to achieve the thixotropy, rheology and anti-settling of the formulation.

We are currently producing in strict accordance with ISO900, and our products have been sold and used in most countries around the world.

organo bentonite For Drilling | organo clay

CP-150 ORGANOPHILIC CLAY

CP-982 Organophilic bentonite

CP-992 Organobentonite

organo bentonite | organophilic clay

Organophilic Clay is an easy dispersing, self activating organoclay that exhibits high performance efficiency in diesel, low aromatic mineral oil, modified vegetable oil and synthetic base fluid formulation.

The role of organoclay bentonite in coatings.

Organic clay bentonite is a good suspending agent in coatings, Especially in the system of solvent based coating, this feature can be better displayed.

At present, modified clay is used in the process of preparation. It can increase the viscosity of the coating and has a certain thixotropic property.

The coating prepared with basic clay can easily increase the penetration of sand mold or sand core, and the thick coating has excellent sand coating performance.

Compared with the coating prepared by lithium-based bentonite, it has better smoother coating surface and less brush hair.

We must remind you that the amount of modified clay material is regulated. He must prove your specific amount in the formula through your experiments. It is not unreasonable to say that the more amount of organo bentonite clay, the better the performance.

Having good gel performance is a major feature of modified clay material, which means that organoclay bentonite has good dispersibility in organic solvents.

that is, some systems have good gel strength mutation and thermal stability similar to water borne modified bentonite .

When organic bentonite is wetted by a large number of organic solvents, low molecular weight polarity, dispersant is sharp rock along the way, and silica moves into the organic cation space between cities in the tetrahedron layer.

Under the melting action of volume, the shape aggregates thin slice.This is the process of dispersion, so organobentonite | modified clay is a kind of easily dispersed coating additive.

Organo bentonite clay CP-150 unique rheological structure suspends weighting materials and other solids with less increase in viscosity and gel strength than conventional bentonite.

It is highly effective in distillate and mineral oil based invert fluids.

Properties

Composition Organically modified bentonite clay

Appearance Off white to tan finely divided powder,

Moisture content (105℃,2hr) ≤3.5%

Specific Gravity 1.7

Bulk density 0.40~0.60g/cm³

Advantages

- Effectively suspends weighting materials and other solids

- Maintains suspension over a wide temperature range

- Eliminates need for chemical activators

- Is easy to disperse and rapid yielding

- Suspends weighting materials and other solids

- Maintains suspension over a wide temperature range

Application

Organo bentonite clay Organophilic Clay CP-150 is a self-activating gallant offering rapid yield development, high gel strengths, and increased efficiency.

The unique properties of drilling bentonite CP-150 are especially valuable in low-shear mud plant operations and during completion fluid manufacture at the well site

Base oil:

- Diesel Oils

- Mineral Oils

- Synthetic Oil

- Linear and isomerized Alpha Olefins

- Modified vegetable oil

Viscosifying drilling Fluids:

- All oil based drilling fluids

- Invert emulsion fluids

- Workover fluids

- Fracture fluids

Safety

All safety information is provided in the Material Safety Data Sheets for Zhejiang Camp-Shinning New Material Co., Ltd.

Package

Kraft paper bag with PE liner or multi-wall paper sacks or customized. 25kg/bag or 22.68kg/bag or customized

Storage

Drilling bentonite CP-150 Store in a dry, well-ventilated area with temperature of 0℃-30℃. Keep container closed. The quality guarantee period is 24 months.

Welcome to inquire about our modified organic clay.