Bentonite Clay Powder Supplier & Manufacturer in China

Whatsapp/Wechat : 0086-13185071071

Bentonite Powder | Organic bentonite clay powder

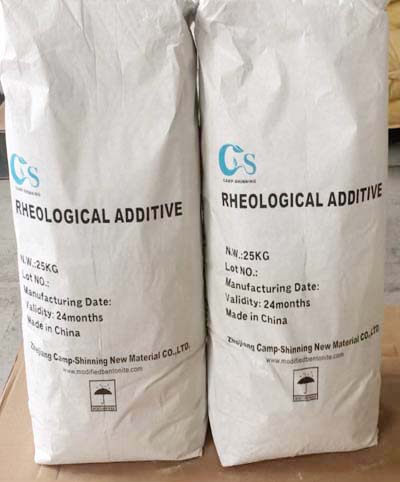

Bentonite Clay Powder : It is a kind of Organic clay form bentonite, which is mainly modified to achieve the universal properties and rheological properties of the bentonite itself, as well as its suspension performance. Its packaging is in the form of 50 lb and 25 kg. We can also customize packaging according to customer requirements. If your project happens to require organoclay bentonite, then purchasing modified bentonite like ours is a wise decision for you.

Organoclay Rheological Additive

bentonite Clay thickener

Camp Shinning produces organic Bentonite Clay Powder thickener with over 20 years of production experience, and the entire process strictly follows ISO standards for production and operation. Its CP series organic clay bentonite is mainly used in major industrial fields such as oilfield drilling, coatings, paints, and frac fluids, among which cosmetics and adhesive are also widely used in organoclay bentonite thickener. Please contact the supplier and manufacturer of organophilic clay bentonite, Camp New Materials is a professional provider provides you with a complete solution for bentonite thickener.

Solvent Paint Grade

Solvent Paint Grade

Organoclay CP-10

Organobentonite CP-10 is used in non-polar to medium polarity aliphatic.

Solvent Paint Grade

Solvent Paint Grade

Rheology additive is a good thixotropic and anti-settling agents.

Water Paint Grade

Rheology modifiers CP-EW is a good anti sagging agent and anti settling agent.

Water Paint Grade

Water Paint Grade

CP-WBS is currently the cheapest water-based bentonite in our company.

Organoclay Supplier / Manufacturer :

Internet address: https://www.rheologymodifiers.com/

Email address: [email protected]

Whatsapp / Wechat: 0086-13185071071

Organophilic Clay Supplier / Manufacturer : Camp Shinning

Bentonite Powder | Arcilla Bentonite

Oil Drilling Grade

Organoclay CP-2

Organoclays CP-2 is a visicosifier for oil field drilling with a very prominent price advantage.

Oil Drilling Grade

Organophilic bentonite CP-982 is used for diesel oil based drilling mud.

Oil Drilling Grade

Organophilic clay CP-992 is used for mineral oil based drilling mud.

Oil Drilling Grade

Organophilic bentonite clay CP-150 is used for synthetic oil based drilling mud.

Grease Grade

Grease Grade

Grease Grade

Organo clay APA

CP-APA is a rheological additive.It’s used in systems from Moderate to highly polar solvents.

bentonite clay powder 50 lb bag | Bentonite 25Kg

Bentonite Clay Powder Packing: 25Kg/Bag or 22.68Kg(50lb) /Bag. 16MT/20FCL with pallet.25MT/40FCL without pallet.

Organoclay Rheology Modifiers for Solvent | Looking for a way to increase the sag resistance of your solvent-based coatings? Camp Shinning has created a rheology modifier that does exactly that! Our modifier prevents pigment sedimentation and provides shear-thinning behavior to your coatings, allowing them to resist s

The final quality and performance of bentonite Clay Powder are directly related to its production process, the degree of its technological, and the strength of the composition and structure of the raw bentonite ore.

In our production process of over 20 years, we have found that we must choose an appropriate purification method based on the characteristics of the bentonite raw ore.

Because there are many new influencing factors proposed by the technical team, such as the speed and time of centrifuges, the type and dosage of dispersants added, and the temperature of bentonite, all of which will affect the final product quality.

So the surface modification of Bentonite Clay Powder refers to the physical, chemical, mechanical and other methods used to treat the surface of organic bentonite.

We will treat the surface of different organobentonite models based on their final application direction, whether it is for their physical or chemical properties,

In order to ultimately achieve the dual advantages of the performance and use value of bentonite clay .

So, in order to fully realize the performance of organic bentonite, we have also carried out dry process and wet activation of bentonite, And pre gel activation.

The method is to directly mix the ground-based bentonite with the covering agent, which has a water content of about 20%.

and then add the mixture evenly before squeezing to make an organoclays bentonite with a certain amount of water, and then dry, crush and grind it to make a powder product.

Sometimes we also add organophilic clay bentonite with a certain amount of water, and directly put it into an organic solvent to make a domain gel or emusision product.

The biggest difference is that when we wet process treatment, we disperse sodium based Bentonite Clay Powder, then make a slurry, purify it, and then carry out activation modification treatment.

After a series of treatments, we transformed it into a hydrophobic organic complex, which was then dehydrated, dried, crushed, ground, and ultimately transformed into a powdery structure of organic bentonite.

And the preparation method of operating Bentonite Powder we just mentioned is actually very similar to wet process treatment, because we need to disperse bentonite, then make a slurry.

and then add organic solvents, such as some base oil mineral oils, to the organic bentonite process after purification and modification.

These can be done, and then extract the hydrophobic organic bentonite complex into the organic solvent, and evaporate it, The residual water is directly made into organobentonite pre gel.

To put it more generally, the quality of raw ore bentonite and montmorillonite of different quality is very different from that of the final organic bentonite.

Montmorillonite can exchange metal cations, and the ion exchange capacity directly affects the quality of organic bentonite.

Therefore, the bentonite needs to be activated before the organic activation. This is the preparation process of organic bentonite that we briefly introduce.

It also allows you to have a better understanding of our process of producing organic bentonite about how do we control our quality?

Finally, we have to mention that most of the organic bentonite produced in China is chemically modified from calcium-based bentonite and then subjected to organic activation, which will result in better quality.

Bentonite Clay Powder Kraft paper bag with PE liner or multi-wall paper sacks or customized. 25kg/bag or 22.68kg/bag or customized

Organophilic clay is an organo clay (modified montmorillonite), designed especially for use in solvent based system including intermediate and low polarity range organic Inks.

- Exerts gelling efficiency over a wide range of intermediate and low polarity

- Easy dispersing

- The gel is colourless and of high clarity

- Produce reproducible thixotropic consistency over a wide temperature range

- Imparts particle suspension, sag resistance without impairing flow and leveling, preventing hard settling of pigment and fillers

- Exerts strong film reinforcing action in organic binder systems

We recommend that you test the sample to get the final result you need. The most important thing is that we hope to verify whether it matches your formula through the test.

Composition Organic derivative of a montmorillonite clay

Appearance Fine powder, white

Moisture content (105℃,2hr) ≤3.5%

Loss on ignition (1000℃) 29%-32%

Bulk density 0.53g/cm3

Fineness (<74μm, %) ≥98%

Email: [email protected]

Whatsapp/Wechat: +86-13185071071

Bentonite Clay Powder, organophilic clay,organobentonite, organo clay