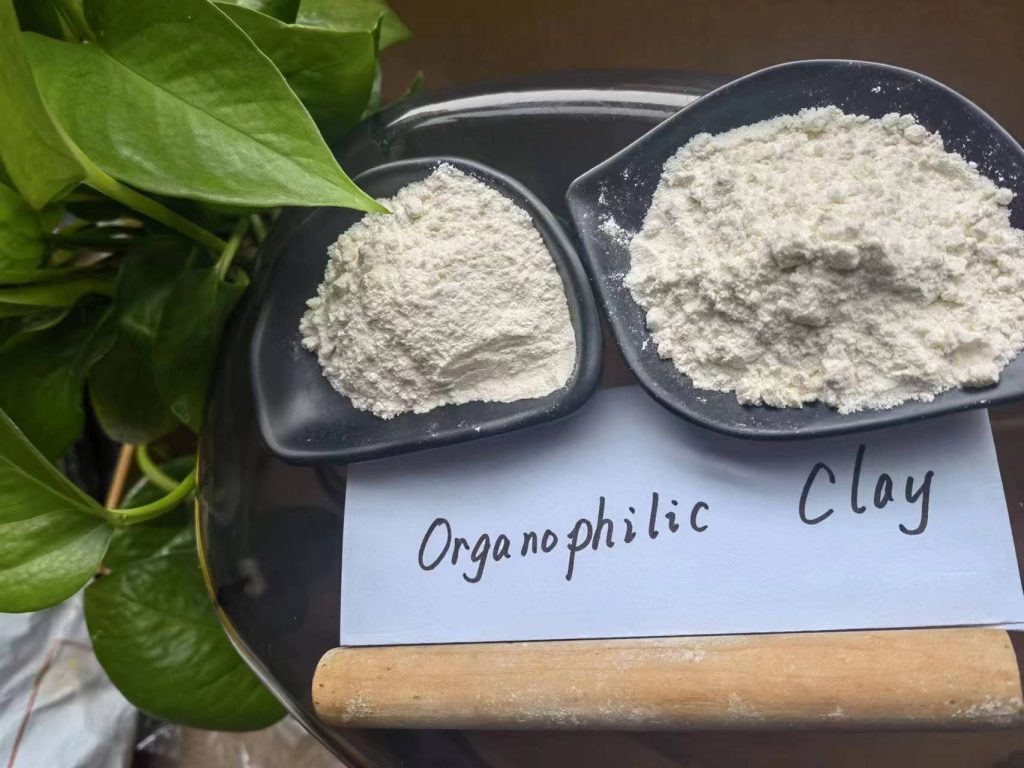

CP-10 Organoclay

CP-10 organoclay is a rheological additive made of organoclay. It is used in non-polar to moderately polar aliphatic and other solvent systems

Organophilic Clay Mineral Process : Camp Shinning have their own raw ore to help our users choose high quality minerals and produce organic clay bentonite with stable performance.

Produce different levels of organoclay bentonite based on different ore layers to match different application fields. If you happen to be purchasing Organophilic Clays from China, contacting our sales team will be your best choice.

At the same time,Camp Shinning’s technical team will also adjust the formula based on your project to achieve maximum matching of the overall formula.

We will also let you know more about our Organophilic Clay Mineral Process .

CP-10 organoclay is a rheological additive made of organoclay. It is used in non-polar to moderately polar aliphatic and other solvent systems

CP-MPZ organoclays is an modified bentonite that is used in solvent and resin systems ranging from non-polar to highly polar.

The CP-MPS rheology modifier is a type of organo clay rheological additive that is used in solvent and resin systems ranging from non-polar to high polarity.

Organophilic Clay Mineral Process

Organophilic Clay and organic ammonium salts are combined in the organophilic clay mineral process. Products made from modified organophilic clay are then produced using this mixture.The procedure for making organophilic clay Chemical reactions involving the addition of organic composition.

Organoclay Supplier / Manufacturer :

Internet address: https://www.rheologymodifiers.com/

Email address: [email protected]

Whatsapp / Wechat: +86-13185071071

Organophilic Clay Supplier / Manufacturer :

CP-EW Organoclay for Water Based paint. It is primarily employed in water borne paint systems,such as latex paint. So it is a good water based additive in paints,coatings,grease etc.

CP-EWS Modified bentonite It is employed in a water-borne coatings system. CP-EWS organoclay outperforms CP-EW in terms of thixotropy, transparence, and dispersion.

CP-WBS Rheology Modifier is rheological modified bentonite. It is mostly employed in water-borne systems.

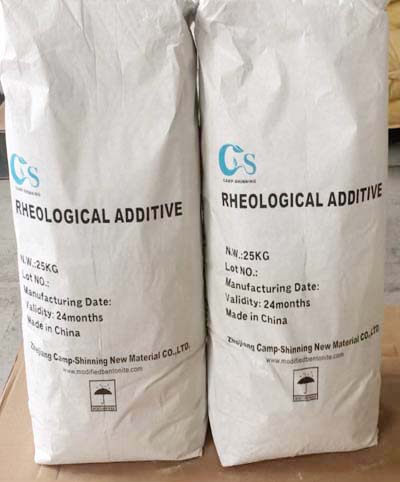

The Organoclay bentonite | Organophilic clay -specialized Zhejiang Camp-Shinning New Material CO.,LTD. and Hangzhou Camp-Shinning CO.,LTD. are subsidiaries of Camp-Shinning.

Camp-shinning concentrated on high value-added, high-technology organo bentonite series products, particularly in research, development, manufacturing, and sales of organic (solvent based organoclay) and inorganic bentonite (water based organoclay).

Our Organophilic bentonite clay finds widespread application in oil drilling mud, paint, coating, lubricating grease, adhesive, construction mortar, cosmetics, and waste water treatment, among other applications. A group of world-class professional users and distributors, such as SUN CHEMICAL,,SIEGWERK,LEHMANN &VOsS, and others, have acknowledged our dependable quality.

Current annual production of organic bentonite clay | organoclay is 20,000 metric tons, while refined bentonite production is 15,000 metric tons.

Our ISO 9001 quality system certification and IS014001 environmental management system certification, as well as our own mine with superior ore quality and production of proprietary technology, ensure the long-term quality and supply stability of our Organoclay bentonite | Organophilic clay.

Our mission is to provide users with superior Organoclay bentonite | Organophilic clay and services and to collaborate with them to achieve success and glory.

Internet address: https://www.rheologymodifiers.com/ and email address: [email protected]

Whatsapp / Wechat: +86-13185071071

Organophilic Clay Mineral Process

Colloidal clay and organic ammonium salts are combined in the organophilic clay mineral process. Products made from modified organophilic clay are then produced using this mixture.

the procedure for making organophilic clay

Chemical reactions involving the addition of organic compounds to clays result in the production of organophilic clay minerals.

The use of organophilic clays as thixotropic viscosifying agents in paints and mineral oils is among their most widespread uses. Moreover, these clays are helpful thickeners for diverse fluids. The process is adding organic material to clay while applying high pressure and little moisture.

Dry process organophilic clays are distinct from modified clays formed from aquatic environments. The forces between the strata are, however, minimal. This enables the introduction of cations and water into the space between the layers. In addition, the layers can change from neutral to ionic depending on the atoms that are substituted.

Making thickeners for paints and mineral oils is one application for the method of manufacturing organophilic clays through slurry. The completed product must adhere to performance standards for paints and mineral oils, thus its purity is crucial. A product free of salt is produced by the aqueous slurry process.

Organophilic Clay Mineral Process

Organophilic clays’ ultimate qualities are influenced by the amount of surfactant used, the temperature and time of stirring, and the surfactant’s composition. The duration of stirring the mixture and the resting period are also quite important in defining the final qualities of the finished product.

The compatibility of clay minerals is another significant characteristic.

Organophilic Clay Mineral Process

One of the most crucial elements affecting how a clay mineral interacts with other substances is its structure. This is so because the structure regulates the double layer that serves as the main source of repulsive pressure’s behavior. Additionally, it regulates the clay mineral’s physicochemical swelling. These attractive forces, meanwhile, pale in comparison to the pressures produced by the outside environment.

The fact that dry-processed organophilic clays are more pure than their aqueous-processed counterparts is another feature of these materials. Additionally, this type of clay can be used to thicken paints and mineral oils. The purity of organophilic clays is not as important for these uses.

Organophilic Clay Mineral Process

There are several ways to manufacture organophilic clay minerals. They can first be made ready by ion exchange with organic molecules.

Once mixed with clay, the chemicals can produce an organophilic clay mineral. Clay minerals that are organophilic are thought to have greater organic liquid gelling capabilities. These clays can then be utilized as viscosifiers for drilling fluids that contain oil.

Organophilic Clay Mineral Process

There are numerous approaches to synthesis organoclay. In one procedure, scientists mixed a clay slurry with an organic cation solution.

A second technique entails combining an organic salt solution with a scattered clay slurry. Because this approach doesn’t employ solvents, it is better suited for industrial use.

Organophilic clays can be produced via the aqueous slurry technique and used as thickeners in paints and mineral oils. Purity is essential for performance metrics in these applications.

This method produces a product with a high level of purity, making it a desirable option for various uses.

It is simple to create organoclay by reacting a clay suspension with specific organic solutions. The end result is an organophilic clay suitable for paint that contains no chloride.

Like attracts like is the basis behind organoclay’s ability to absorb substances. Solubility in water is an important factor in the immobilization process.

Organophilic Clay Mineral Process

Nanocomposites can also be created using organophilic clays. They are suitable for creating polymer-based nanocomposites.

Organoclay Supplier / Manufacturer :

Internet address: https://www.rheologymodifiers.com/

Email address: [email protected]

Whatsapp / Wechat: +86-13185071071

Organophilic Clay Supplier / Manufacturer :

CP-180 organoclay is an organo clay rheological additive (modified montmorillonite) designed specifically for use in solvent-based systems

CP-34 organoclay is a modified bentonite that has been specifically designed for use in solvent-based systems.

CP-EDS modified bentonite is a kind of organo clay rheological additive. It is used in systems of medium polarity and high polarity system.

CP-992 Organophilic Clay, the wet process improved viscosifier and gelling agent . It is a rapidly dispersing.

CP-982 Organophilic Clay is an amine treated bentonite with a moderate temperature performance.

CP-150 Organophilic Clay is a self-activating organoclay that disperses easily and performs well in diesel, low aromatic mineral oil, modified vegetable oil, and synthetic base fluid formulations.

Organophilic Clay Mineral Process